MasterRouter - Strategic Planning Platform

Pre-plan Sales Teams, Field Workers and Delivery Visits

Ensure you have the right team size and makeup, the right territories, and the right routes.

Maximize productivity and streamline your operations. Pre-plan your master routes based on visit frequency for different customer types with advanced route planning.

- Territory Level Planning - What is the most optimal way to define your regions and territories and allocate customers to depots and managers?

- Resource Level Planning - How many resources do you actually require and what is the best set of days to visit each customer?

- Routing Level Planning - What is the ideal way to combine allocated customer visits into optimal routes?

Industries

Sales & Merchandising

Visit more clients with the optimal sales team size. Generate schedules and routes that cater for each customer’s visit requirements. Reduce travel time and increase face time and find the correct number of resources needed for a given visit strategy.

Field Service

Optimize route and technician assignments to the best service areas. Build master routes that leave a buffer to assign emergency and ad-hoc visits while minimizing the impact on regular maintenance.

Home Health

Create optimal routes and schedules that are workable and adhere to patients’ needs and treatment schedules.

Waste Disposal

Generate ideal pick-up schedules handling both increased volumes during holiday periods and once-off events. Quickly re-configure routes for growing areas. Keep an eye on costs of collection routes with tariff verification.

Water Deliveries

Combine delivery frequencies, stores and routes to get optimal plans. Use any planning cycle from one to twelve months. Add in new customers or remove customers with minimal disruption to the current plan. Build new plans taking into account the last visit date.

Industrial Hygiene

Quickly generate new working schedules for managers who are adding new clients to service areas while ensuring regular services to existing clients. When creating a service agreement you can simulate, identify and cost in additional staff if required.

Bread Delivery

Bread delivery can run on different frequency cycles – daily, every two or every three days. Whatever the frequency, delivering bread is a low margin high intensity operation that must be managed with science and skill to achieve maximum utilization and minimum costs.

Auto Parts

Delivering auto parts to body shops and mechanics is complicated by short promise times, multiple trips per day and variable demand on trips. The challenge is to use historical data to create master routes that allow for high reliability in delivery while minimizing vehicle and driver costs.

Store Replenishment

When replenishing stores from a central warehouse there is often a wide range of required frequencies. High volume stores may require two visits a day, while smaller stores may only need one visit a week with all possible frequencies in-between. Harmonizing these widely variable cycles is a challenge when you want to make sure that your trucks are full and your mileage is minimized.

MasterRouter Features

MasterRouter Benefits

Streamlined Operations

Ensure that your operations are as streamlined as possible while not sacrificing customer service and SLA compliance.

Happier Customers and Employees

Improve your on-time delivery and visit accuracy with better routing while ensuring that workloads across your team are balanced.

Save Both Time and Money

With better routing and planning you can reduce your team size while also decreasing distance travelled -- saving lots of time and money.

MasterRouter Case Studies

Read about some of our success stories.

NDD Case Study: Bottled Water Delivery Company

A company that delivers bottled water in the UAE on nominated delivery days needed to find a way to balance the workload amongst the team while reducing their costs. Discover how in the case study.

Master Routes Case Study: Milk Deliveries

See how MasterRouter helped a dairy farm in India to optimize their milk deliveries – improving the total distance travelled by 43%.

Region Cutting Case Study: Daily Sales Routes

A large confectionary manufacturer in India needed to optimize their daily routes for over 5000 sales reps. See how MasterRouter created ideal routes for the sales reps while enabling more outlets to be visited at a lower cost.

Sales Rep Case Study: Large Beverage Manufacturer

A large beverage manufacturer with over 700 sales reps and 100,000 outlets used MasterRouter to create optimal daily sales rep routes for reps of varying skill levels. See how MasterRouter helped shape their schedule and save the company over 5 million travelled kilometers annually.

NDD Case Study

Introduction

A company that delivers bottled water in the UAE on nominated delivery days needed to find a way to balance the workload amongst the team while reducing their costs.

The company was using eight vehicles to complete deliveries to 1121 customers with visit frequencies varying between once in the period to daily.

The Challenge

The vehicles were traveling over 10,000 kilometers daily and the company wanted to reduce this. In addition, the workload was skewed so that some reps were working much harder than others. The company needed to balance the workload across all of its reps.

The Results:

When MasterRouter was given the freedom to select both the visit days and the reps, the daily kilometers driven reduced by over 30% – from 10,616 km to 7301 km. In addition, MasterRouter did a fantastic job at evening out the workload.

Master Routes Case Study

Introduction

We were approached by a dairy farm in India to optimize their milk deliveries. See how MasterRouter created ideal routes – improving the total distance travelled by 43%.

The Challenge

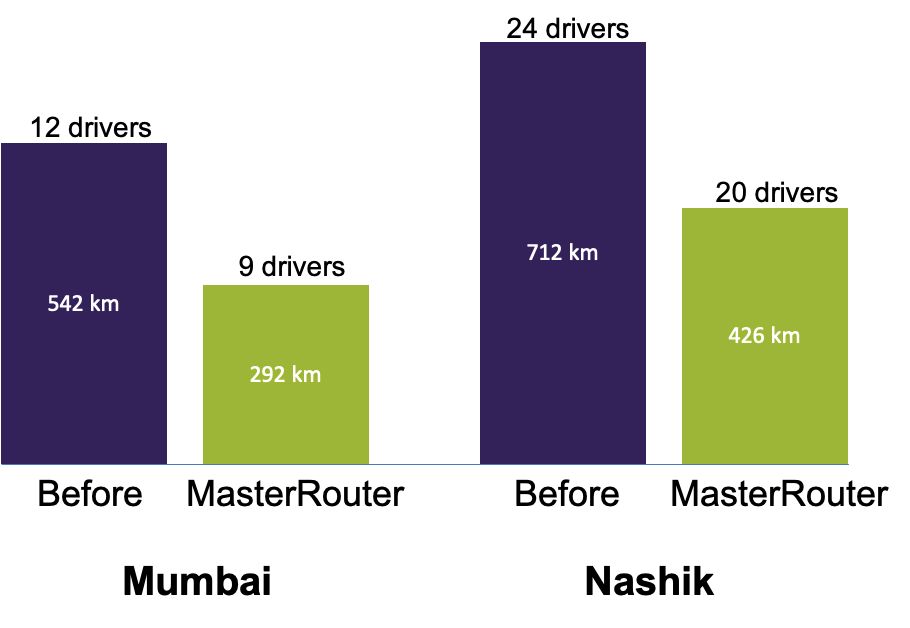

The depot in Mumbai had 297 contracts that were serviced by 12 moped drivers while the depot in Nashik had 599 contracts that were serviced by 24 drivers. For both cities, the drivers completed their routes in about 1H30M (Mumbai = 1:33 / Nashik = 1:27).

The Results:

While drivers in both cities maintained an average route time of about 1H30M, Mumbai could complete their routes with 9 drivers instead of 12 and Nashik needed 20 drivers instead of 24.

With a decrease in the number of drivers and better routing, the total distance travelled by drivers dropped by 43%. The average distance driven dropped by 28%.

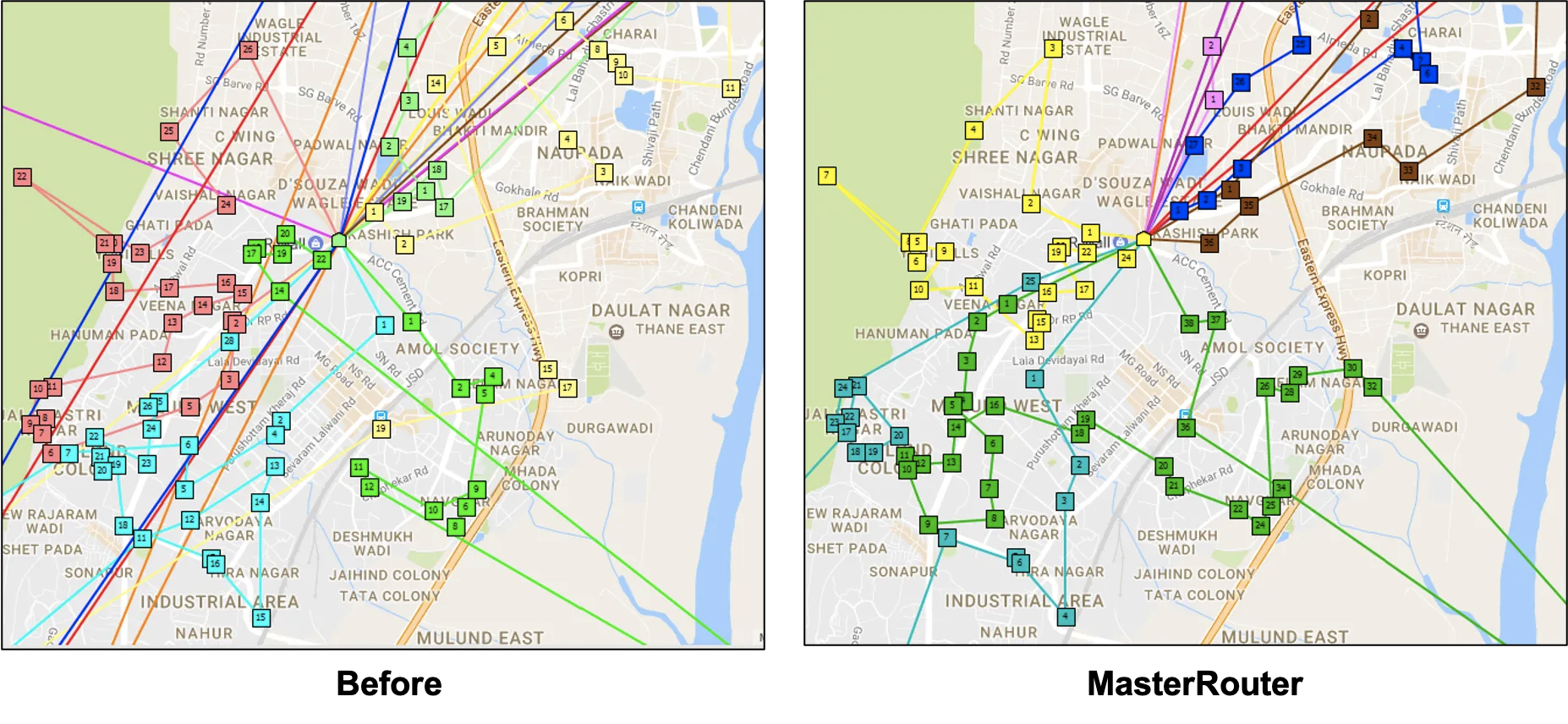

Looking at the before and after pictures of the routes of Mumbai, it is easy to see the improvements that MasterRouter has made. The outlying customers in the western portion of Mumbai were previously being visited by five different drivers while now they are visited by the same driver.

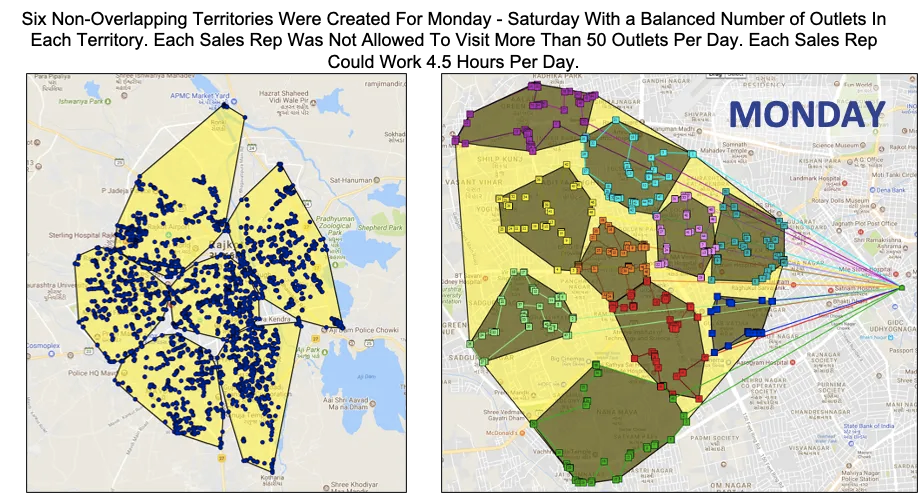

Region Cutting Case Study: Daily Sales Routes

Introduction

We were approached by a large confectionary manufacturer in India to optimize their daily routes for over 5000 sales reps. See how MasterRouter created ideal routes for the sales reps while enabling more outlets to be visited at a lesser cost.

The Challenge

For each delivery-day region, we needed to further divide those up into sales rep territories. It was very important that these territories did not overlap as well as that the number of outlets in each sales rep’s territory were balanced.

In addition, a rep could not be expected to visit more than 50 outlets a day and the reps had 4.5 working hours a day.

The Results:

The company has been able to realize a 15% improvement in the number of outlets that are visited at an overall reduction in costs of 10%. Within this, there’s been a 12% overall reduction in mileage driven and an 8% reduction in staff required.

Sales Rep Case Study: Large Beverage Manufacturer

Introduction

We were approached by a large beverage manufacturer to create optimal daily sales rep routes for reps of varying skill levels for over 50,000 outlets. See how MasterRouter created ideal routes for the sales reps, adhering to the skill-level constraints, and saving the company over 5 million kilometers annually.

The Challenge

For the initial study, we were given the data for 684 reps over 21 districts. We were also given the outlet locations for over 50,000 outlets with a required visit frequency of up to 6 visits. The planning period was 4 per week and 5 per day.

In addition, the sales reps were divided up by skill level.

The outlets were also categorized by type of outlet and which type of rep was allowed to visit them: some were allowed to visit all of the outlets while others were only allowed to visit those outlets appropriate to their skill levels.

The Results:

MasterRouter was used to regionalize both the outlet types and which reps were allowed to visit them. Each set of regions was categorized into regions.

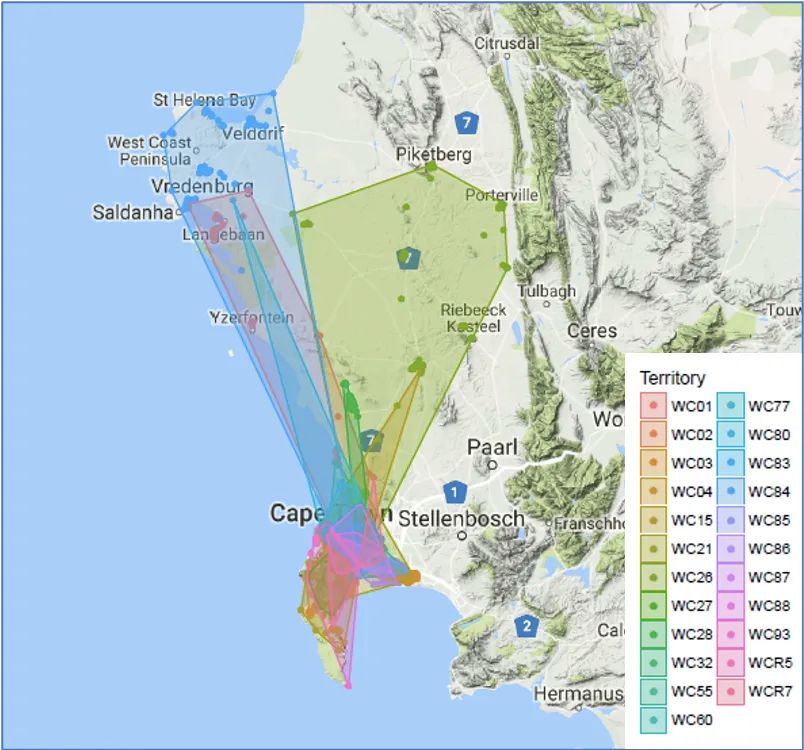

For the “Inland District” region (see image below) there were 23 sales reps assigned (8 HAM and 15 AM) to 1813 outlets. 5 of these reps had sleep-outs and an average of 16 outlets were visited daily and the average daily travel distance was 79 km.

This methodology was applied country-wide. All outlets were now being visited by the correct personnel according to all required contract periods and SLAs, and, this was done much more efficiently with over 5 million kilometers of travel distance being saved annually.